Modern buildings may be equipped with advanced BMS platforms, but that doesn’t mean they capture everything. Are lights really turned off after hours? Are ACs running when no one’s around? Is indoor air quality truly being monitored? From commercial towers in Dubai to government offices in Abu Dhabi and retail complexes in Bahrain, this article shares five real-world lessons that expose the blind spots traditional systems miss. Discover how wireless sensors, edge IoT gateways, and AI-powered analytics bring unseen inefficiencies to light, and turn data into action.

Let’s dive in… How wireless sensors, edge IoT gateways, and AI analytics close the gaps traditional BMS platforms leave behind.

1 | “We already switch the lights off every night”

But Smart Lighting Still Cut Our Bills

In a Dubai commercial tower, the facility manager was confident: every night, security guards walked the floors and turned off all the lights manually. Still, electricity bills kept climbing. A quick energy audit revealed what wasn’t visible: lobby spotlights, corridor lamps, and kitchen hoods were frequently left on after hours. They are often powered by hidden or hard-to-access circuits.

After deploying LoRaWAN smart light controllers and motion-based triggers, the lighting system followed actual occupancy patterns. The project took less than a day to install, with wireless relays connected to 87 lights across 8 circuits. In the first month, lighting energy dropped by 25%, and the facility team finally gained control without extra labor.

2 | “Split ACs are too small to worry about”

Until 150 of Them Run at Once

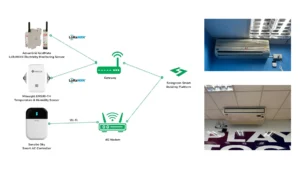

At a large call center campus in Davao City, over 150 inverter split AC units cooled multiple zones. Each unit used a wall-mounted remote, meaning some stayed running during breaks, weekends, or even after closing time. Facility teams believed their timing was tight until they saw the data.

With smart split AC control Philippines using Sensibo smart modules and centralized AC dashboards, the entire site gained real-time visibility. The platform optimized temperature settings based on room occupancy and working hours, allowing remote control, scenario-based automation, and energy tracking. The result? A 12% drop in electricity bills, 6,000 fewer cooling hours each month, and improved comfort for employees.

3 | “Our old building blocks new tech”

But LoRaWAN Got Through

In Abu Dhabi, a 20-year-old government building had strict limitations. Drilling walls for sensors was not allowed, and LAN access was restricted due to cybersecurity protocols. Still, the building required reliable CO monitoring to protect 250+ employees and comply with UAE air quality regulations.

The solution? A 5G-enabled LoRaWAN CO monitoring system. Wireless Nexelec CO sensors were installed without any infrastructure changes, and data flowed directly to the Sensgreen Platform via a dedicated 5G network. The platform generated real-time alerts via WhatsApp and e-mail. Response time for CO incidents dropped from 30 minutes to 5. The building remained 100% compliant without touching its internal network.

4 | “Our BMS shows everything we need”

Except the Air We Breathe

A retail complex in Bahrain had a modern BMS that showed chilled water temps, valve positions, and air handling unit speeds. But when they installed 30 IAQ sensors measuring CO₂, humidity, and PM2.5, nothing appeared on the BMS dashboard. The sensors used LoRaWAN, not BACnet.

The fix was simple: an edge IoT gateway from Sensgreen bridged the gap, translating LoRaWAN packets into virtual BACnet points. Without changing the interface or retraining the team, the mall gained live visibility into indoor air quality directly on their existing platform. Operators could now cross-check IAQ metrics with HVAC data and respond proactively to comfort issues.

5 | “A monthly PDF report is enough”

Until AI Made It Instant and Actionable

In a Dubai-wide real estate portfolio, engineers in 80 buildings were producing performance reports manually. It took up to 4 hours per building to compile screenshots and write summaries. The reports were late, and actionable issues, like clogged filters or humidity anomalies, often went unnoticed until tenants complained.

Today, the same reports are generated by an AI-powered facility management engine. The system analyzes alerts, groups them by root cause, and sends out a Monday action plan via e-mail: fix two schedules, check one sensor, replace three filters. Reporting time dropped to 15 minutes, and interventions now happen within the week, not the month.

Why These Lessons Matter

All five facilities already had a BMS. But what they lacked was visibility into the unstructured, untracked, and underreported layers of their operations. By adding wireless sensors, an integration gateway, and AI-powered reporting, they revealed where the actual inefficiencies hid, and acted faster.

Want to see the blind spots in your buildings?

Request a two-day pilot kit or book a live demo to see how real-time data flows into action, without changing your existing systems.